Digital workflows are now easily accessible. For example, the new Digital SMART Flow system from Elos Medtech which includes all the tools—scan bodies, hybrid bases, pre-milled blanks and abutments—needed for digital workflows, all of them FDA cleared and MDR compliant where required. As for costs, relentless innovation and investment have put digital workflows within reach of virtually any dental professional.

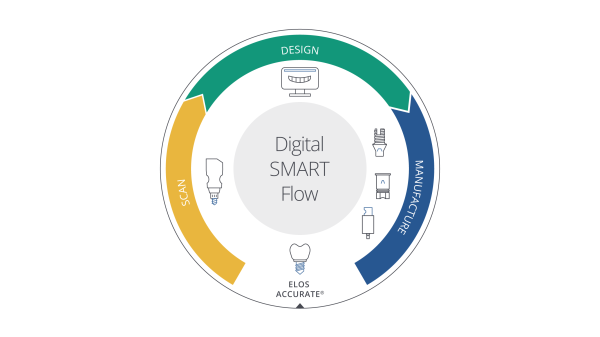

But it is the basic design philosophy behind Digital SMART Flow that makes it such a convenient stepping-stone into digital workflows. That’s because rather than a mere collection of standalone components, Digital SMART Flow is an interlocking system of products, each aligned to the three key phases in the digital workflow: scanning, design, manufacturing.

The first phase, accurate scanning, is enabled by the Elos ScanBody22™, a single-body, all titanium scan body offering unrivalled accuracy. The second phase, design, is made possible by the Elos Accurate Library, helping you maintain design consistency over time. The final phase, manufacturing, is supported by our product portfolio that enable labs to achieve predictable outcomes and meet all regulatory requirements.

Digital SMART Flow is a particularly exciting concept in the ongoing democratization of digital dentistry. As the name indicates, the new concept aims to eliminate complexity from digital workflows, with SMART standing for: Simplify the Manufacturing of Accurate Restorations with Technology. There are several ideas at work here, so let’s unpack them one by one.

A closer look at SMART Flow

‘SIMPLIFY’ refers to the ease-of-use and convenience of the digital workflow enabled by Digital SMART Flow. You are, for example, free to start the workflow with a digital impression from an intra-oral scanner or a conventional impression. You can continue the workflow entirely digitally, or mix conventional with digital, such as by making a plaster model and scanning it with a lab scanner.

Digital scanning is the entry point into digital workflows you can have confidence in, something made easier than ever with the inclusion of a new scan body, the ScanBody22™, in the Digital SMART Flow range of products. In fact, thanks to its new AccuScan® coating, the ScanBody22™ is probably the most accurate scan body on the market. Made from titanium—the benchmark in biocompatible metals—the manufactured-in-Denmark ScanBody22™ also features a unique ‘window’ that keeps the screw in place, and enables easy yet thorough cleaning. And as it is autoclavable up to 100 times, the ScanBody22™ can be safely reused for multiple scannings.

‘MANUFACTURING’ refers to the smooth digital flow from design to final milling of the restoration. During the design phase, you simply upload the Elos Accurate Library to any approved dental CAD software. Once the design work is complete, you receive the STL file that can be opened with all major CAM software suites.

You are free to choose to mill your dental restoration in-house or at an FDA-registered Elos Medtech approved milling facility.

Physical boundaries are erased as digital impressions can be sent across the globe in the blink of an eye. By receiving a digital file, prosthetic constructions can be designed directly in the CAD software before sending it to a 3D-printer or milling machine. This means fewer steps and a minimized risk of error.

‘ACCURATE RESTORATIONS’ refers to the concept’s focus on accuracy, such as that demonstrated by the new ScanBody22™. Indeed, one highly respected practitioner described the performance of the ScanBody22™ as “an evolutionary advance in accuracy,” that will “help minimize the risk of adjustments further on in the workflow.” The unwavering commitment to accuracy of course characterizes all products in the Digital SMART Flow portfolio: hybrid bases (ti bases), implant analogs for exceptional accuracy in 3D printed models, prosthetic screws, pre-milled blanks, and of course, our open library containing all relevant CAD / CAM parts for 3Shape and exocad software.

Finally, ‘TECHNOLOGY’ refers to the technical excellence of the Digital SMART Flow solution. Then again, technical excellence is in our very DNA. For more than a quarter of a century, Elos Medtech has been a partner and subcontractor for all the major dental implant companies. In fact, it was Elos Medtech who together with 3Shape, developed and introduced the original PEEK scan body featuring a titanium interface. Today this design is the gold standard for scan bodies—copied all over the world.

Elos Medtech also developed pre-milled abutments (prefabricated blanks) for making customized abutments. Further innovation later led to our patented design for the Elos Accurate Analog for printed models, an advance that overcomes many of the challenges posed by 3D printers.

So what now? This article sketches some of the features of our Digital SMART Flow concept—and only hints at the benefits it offers labs, clinics, implant companies and patients. To learn more, visit https://elosdental.com/digital-smart-flow, or email dentalsupport@elosmedtech.com