When replacing lost teeth, the aesthetic aspect of the result is just as important as to restore functionality. In this clinical case, a digital workflow provided a comfortable treatment as well as a precise, functional and aesthetically appealing result for the patient. Here is how dental clinic Centre of Dental Specialist Care together with dental laboratory DentalSyd carried out the treatment using an intraoral scanner and Elos Medtech’s Elos Accurate® Scan Body and library.

DentalSyd – Providing dentists with high-quality prosthetics restorations

Dental specialist clinic Centre of Dental Specialist Care in Sweden is specializing in oral prosthetics. Together with dental laboratory DentalSyd they carried out the treatment. DentalSyd specializes in bite rehabilitation cases and to create prosthetics restorations with optimized functionality and aesthetics. They aim to function as a resource for the dentists they cooperate with. Both regarding therapy planning as well as visualization of the patient’s new smile by physical models or computer environments.

Implant treatment with aesthetic as well as functional goals

This clinical case started with a patient that, after suffering trauma to the head, was referred for treatment and replacement of lost teeth in the front region. The absence of the teeth caused a lot of discomfort and inconvenience for the patient that had trouble biting and expressing certain sounds. In addition, the patient felt insecure in social situations because the gap from the lost teeth was so visible when smiling and talking. Hence, the patient’s needs were both aesthetic and functional.

Dental technology and products that simplify the digital workflow

Scanning with an intraoral scanner to enter the digital workflow

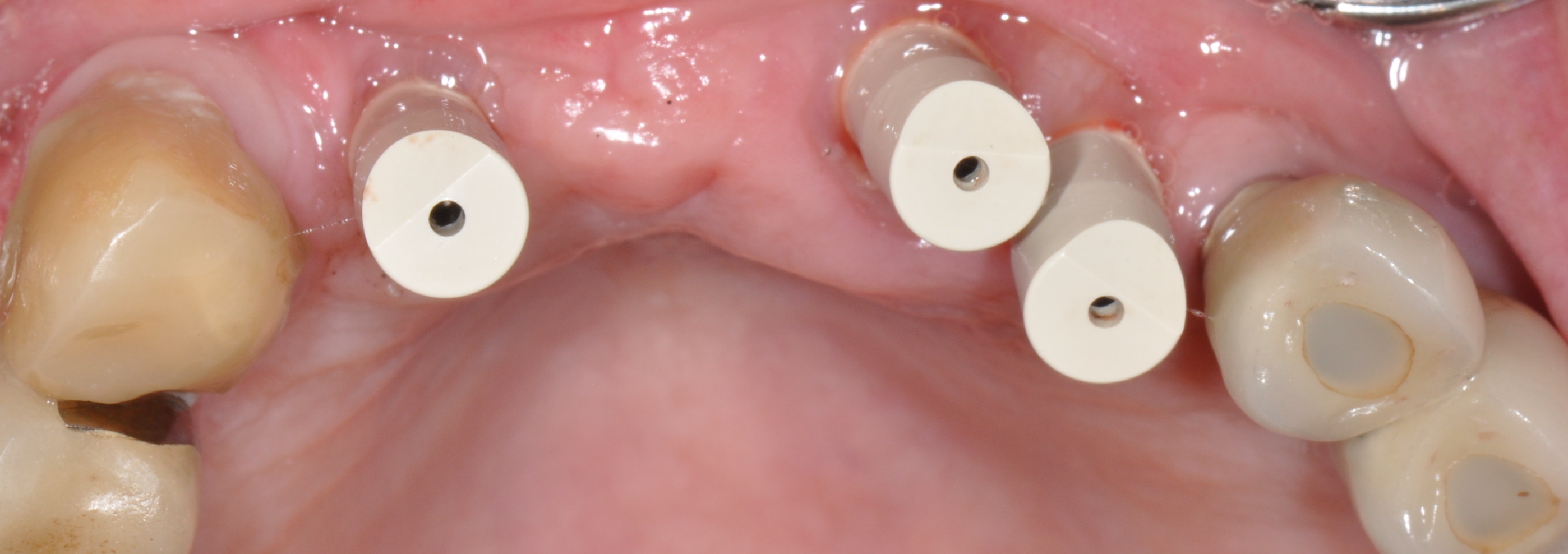

The implant treatment began with a two-stage surgery where three implants with healing abutments were installed. After four months of healing the patient returned to the clinic. The healing abutments were scanned with an intraoral scanner and then replaced with three Elos Accurate Scan Bodies. When the scanbodies were in place, they too were scanned with the intraoral scanner.

Creating an anatomical pre-design of the prosthetic construction

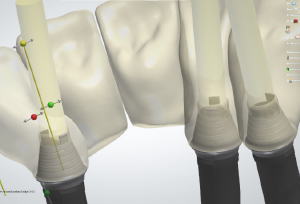

The resulting digital files from the scanning were sent to the dental laboratory where the CAD software 3Shape Dental Designer was used to perform the following stages of the process. In the software, the Elos Accurate Scan Body functioned as a reference to align and position the material file from the Elos Accurate Library. The next step included creating an anatomical pre-design of the prosthetic construction using the software and the digital files.

Milling, cementing and mounting of the bridges

When the design of the bridge was finalized and the Elos Accurate Hybrid Base Bridgehad been placed into the bridge in the software, it was milled in-house.

The model analogs were placed into the model from 3D medical print and three Elos Accurate® Hybrid Base Bridge were placed in the milled construction and cemented at the laboratory. The finished prosthetic construction was then sent back to the clinic and installed to the patient with a successful result.

A comfortable dental implant treatment with high precision result

The patient’s aesthetic and functional needs required an implant treatment with high precision. The digital workflow contributed to meeting these requirements. When scanning teeth intraorally with Elos Accurate Scanbody, the dentist gets immediate feedback if the scanning is adequate or if it requires any adjustments. This is helpful to maximize the chance that the construction will have a perfect fit without the need to do subsequent adjustments. Apart from this, it also makes for a more pleasant experience for the patient in comparison to the quite uncomfortable, traditional impression technique.

By using Elos Accurate Scanbody, the dental libraries are accessible via the scanner software. This too enables high precision work. Using the Elos Accurate Library instead of scanning the titanium base means that there is no need to blast or paint the titanium base beforehand. This procedure can cause damages and inaccurate cement gap possibly resulting in a badly fitting dental construction. Since all necessary parts are available in the library it is possible to complete the entire design process in a digital workflow and create a finished dental construction with an optimized fit.

“We are very satisfied with how the treatment progressed and the patient is happy with the result, which is the most important aspect. Our cooperation with Elos Medtech plays a large role in this and we are looking forward to our future projects together”, says Dr. Jenö Kisch, DDS OD h.c.Senior Consultant, Specialist in Prosthodontics and Periodontology at the Centre of Dental Specialist Care, Malmö, Sweden.

I hope this blog article provided you with knowledge and inspiration to use in your own dental implant work. If you want even more detailed information about the case, read the full report! Feel free to share this blog article on social media, contact me with any questions or visit our website. For more interesting blog articles, visit our Knowledge Blog.