Cresco revolutionized the dental industry when it was first introduced to the market almost 30 years ago. Today, the method’s key benefits of angled screw holes and passive fit are achievable in a digital workflow as well. Therefore, more and more dental professionals replace the conventional techniques with digital ones when creating bridge restorations. We are now phasing out Cresco products and focusing entirely on our digital solutions instead.

Cresco – Prosthetic solution for screw-retained bridge restorations

The journey of Cresco started in 1987 in Kristianstad, Sweden. At that time, dentists and dental technicians worked with dental implants the traditional way, with casted bridgework, and it was often troublesome to get them to fit perfectly to the implants. Cresco was developed as a way of creating screw-retained bridge restorations with a perfect passive fit, independent of implant system or framework material.

Combining the benefits of conventional and digital techniques in the dental industry

A lot happened in the dental industry during the following decades. The digitalization and its advantages of higher precision and reliability led more and more dental professionals to embrace a digital workflow. Many new technologies emerged on the market, such as digital prints, 3D-printing and various types of scanning techniques. Even so, the handicraft and benefits of conventional restoration methods are still there, just upgraded and digitized. Angled screw holes, freedom of choice regarding framework material, passive fit and ease of use are what made Cresco revolutionize the dental industry back in the days. And these elements are of great value to dentists and dental technicians working with bridge restorations today as well. Therefore, it has been important for us, at Elos Medtech, to keep and build upon these when developing our new digital solutions.

Smooth prosthetic process with a digitalized bridge restoration solution

Elos Medtech has been manufacturing Cresco components ever since 1987. In 2014 we took over the entire business from the previous owner. As a way for Cresco to simplify the workflow for their users, they offered an All Parts Included kit, the Cresco API, containing everything needed to carry out the prosthetic and laboratory procedures. To maintain Cresco’s streamlined and straightforward prosthetic process, we kept the concept of the API but added even more features to it. This way, our solution enables a smoother and easier workflow with an even more aesthetically appealing result.

Today, we have developed the Cresco system and our own product range even further and turned it into a complete digital workflow named Elos Accurate® . All products within Elos Accurate are included in our free and open dental libraries which can be downloaded from our webpage and uploaded in the scanners: 3Shape, Dental Wings and Exocad. Our digitized bridge solution is available for the most common implant brands and, as with Cresco, you only use one screwdriver regardless of implant manufacturer or platform.

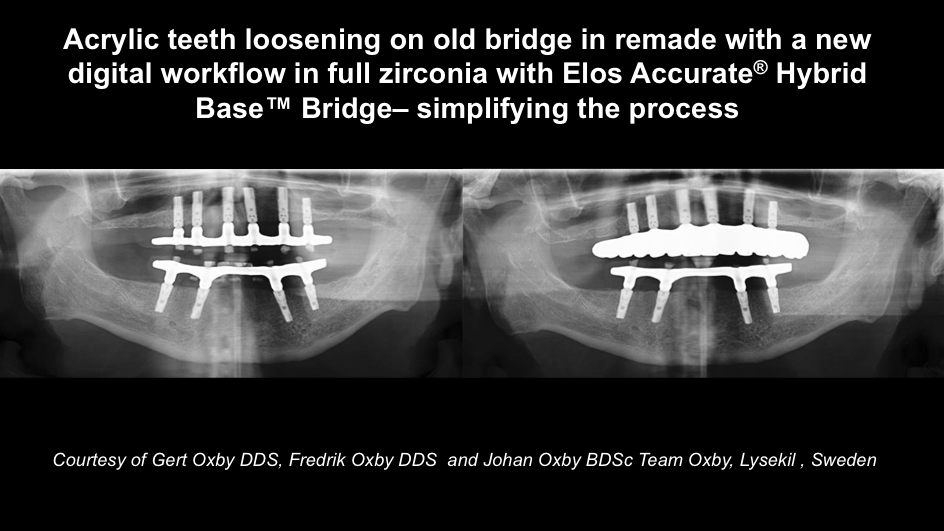

Renovate old Cresco bridge with a higher quality Elos Accurate Hybrid Base Bridge

As more dental professionals are moving into a digital workflow, the demand for Cresco products has decreased. We have therefore decided to not continue producing them but focus solely on our digital solutions instead.

Virtually any case which was previously addressed using Cresco can be completed with our Elos Accurate API Bridge. Repairing and replacing an old Cresco bridge with a better quality Elos Accurate Hybrid Base Bridge is also possible. The picture above shows an example of this. The patient in the picture had the Cresco restoration for almost 10 years before the acrylic started to come loose, while the bridge was still intact and highly functional. At Team Oxby in Lysekil, Sweden, dentists and dental technicians have implemented a digital workflow to renovate old bridge restorations like this one, in a smooth and effective way. Using an intra-oral scanner, CAD software and a milling machine, the end result is an aesthetically appealing restoration with a high quality and perfect fit.

In one of our upcoming blog articles, dental technician Johan Oxby will give you a more in-depth view of how to achieve this. Stay tuned for that!

The Cresco products we still have in stock will be available until May 15, 2018, but products that are out of stock are no longer available for purchase. If you have any questions regarding Cresco or our digitized bridge solution, feel free to contact us! Also, visit our website for more information and our Dental Blog to read other blog articles.